Overview

BNNT presents similar thermal conducting and mechanical properties compared to CNT, while its thermal/chemical stabilities, biocompatibility, electric insulating, and thermal neutron absorbing properties are much higher than those of CNT. Due to these superior properties, BNNT is currently under exploration in many areas of IT, space/nuclear, bio-medical, and energy.

Product Specifications

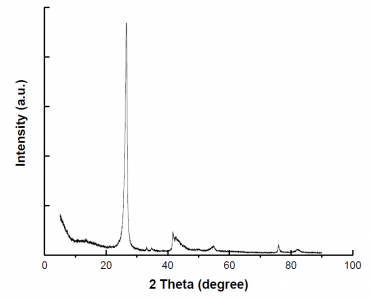

| Attribute | Measurement |

|---|---|

| BNNT Content | > 50 % by Mass |

| Elemental B (free) | < 1 % |

| Residual Content | <24% h-BN and BNH derivatives |

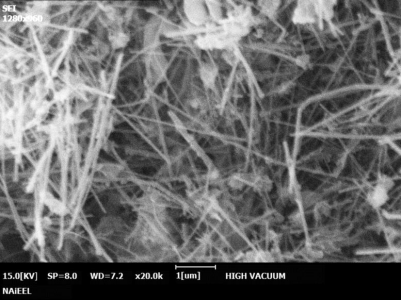

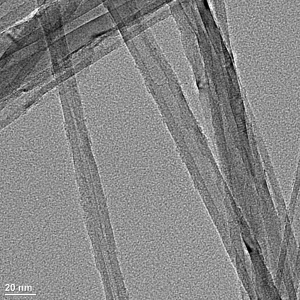

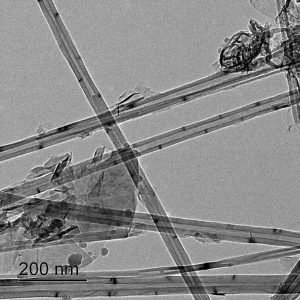

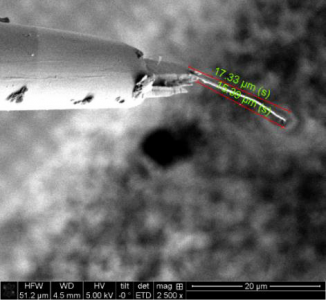

| Tube Length | ≤ 200 µm |

| Average Nanotube diameter | 50 – 100 nm |

| Surface area (BET) | > 30 m2/g |

| Color | Gray |

| Electrical Conductivity | Large band gap insulator ~5.5 eV |

| Optical proprieties | Can be made transparent in visible and infrared regions |

| Thermal Stability | Stable in highly oxidizing (or corrosive) environments, e.g. ~900 °C in air. |

| Neutron absorption | 767 barns (boron, ninth highest) |

| Synthesis | Proprietary |

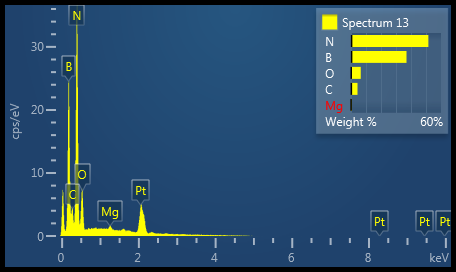

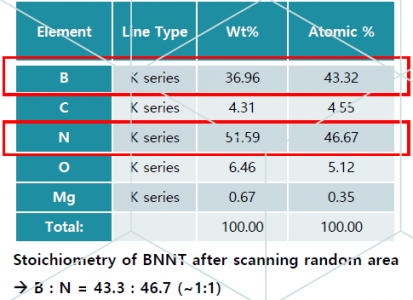

Elemental Properties

Physical Properties

| PURITY | ~80% | >90% |

|---|---|---|

| BET Surface Area | >32.90 m2/g | ~50 m2/g |

| Molecular Cross-Sectional Area | 0.1620 nm | — |

| Diameter | 30-50 nm | 30-50nm |

| Length | ~9 ㎛ | >10 ㎛ |

| Characteristic | CNT | BNNT |

|---|---|---|

| Electrical properties | Metallic or semiconducting | Always semiconducting (>5 eV wide band gap) |

| Thermal oxidation resistance | Stable up to 300-400℃ in air | Stable up to 800℃ in air |

| Thermal neutron absorption (b = 10-24 m2) | 0.0035b | B ~760b / N ~1.9b |

| Thermal conductivity | 60 ~ 40,000 W/mK | ~3,000 W/mK (Cu ~400 W/mK) |

| Mechanical properties (Young’s modulus) | 1.33 TPa | 1.18 TPa |

| Coefficient of Thermal Expansion | ~1 x 10-6 | ~1 x 10-6 |

| Color | black | White (grey if impurity exists) |

Product Applications

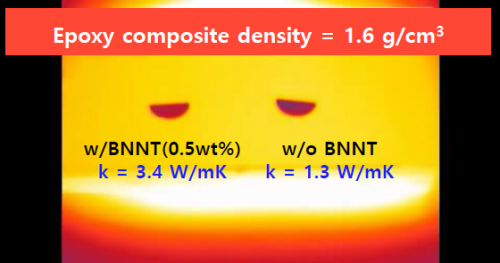

The primary usage for BNNT is to have the material serve as a Thermal Conductor. The thermal conductivity of a material can be multiplied by the incorporation of BNNT within composite materials. Along with this, BNNT-MWs can also provide Electrical Insulation to materials utilized for information technology devices.

Electrical Insulating Thermal Conducting Material for IT Devices

In a Thermal Conductivity Comparison of 50wt% h-BN dispersed epoxy composite and 0.5wt% BNNT/49.5 wt% h-BN dispersed epoxy composite, Thermal conductivity (1.3 W/mK) was be enhanced as much as 3 times (3.4 W/mK) with only 0.5 wt% BNNT-MW (0.5 wt%). Additionally, this material at a BNNT density of 2.0 g/cm3 could provide a thermal conductivity of 10 W/mK. Furthermore, the Electric Breakdown Voltage for these prepared composites was 26.3 kV/mm.

| Electric Measurement | ||

|---|---|---|

| I (µA) | R (ohm) | P (W) |

| 240 | 290.82 | 1.68E-05 |

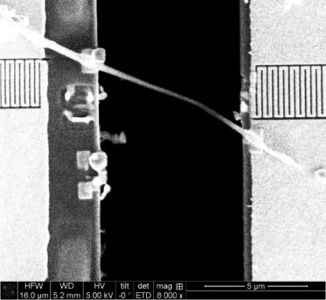

| BNNT Dimension | |||

|---|---|---|---|

| Diameter (m) | Length (m) | Area (m2) | k(W/mK) |

| 2E-07 | 9E-06 | 1.256E-13 | 585.6 |

Kilogram and metric ton price quotes available by request. Additional discounts also available for large volume orders.

For further details, reach out to our Sales Manager at sales@raymor.com or call +1 450.434.6266.

Large volume discounts available for large quantities. Please contact us for more information.