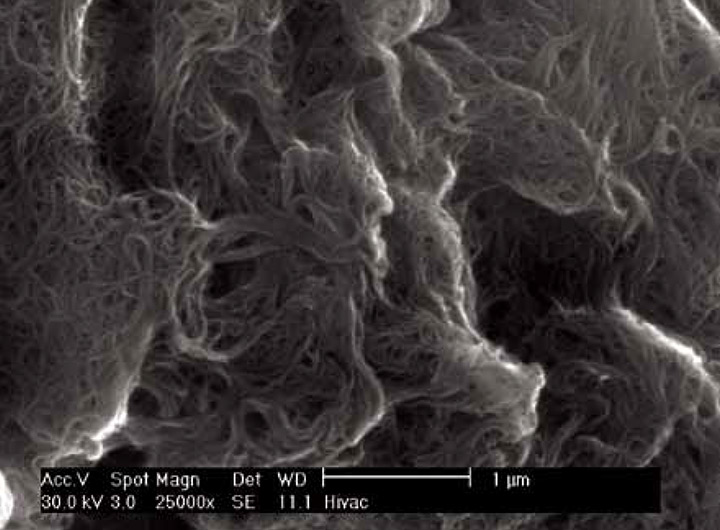

HiPco SWCNT represent a benchmark for small diameter nanotubes both in the academic community and for industrial and commercial applications. We offer three grades of purity for this unique material. Raw HiPco SWCNT contain up to 15% of iron, whereas Purified HiPco SWCNT and Superpurified HiPco SWCNT contain less than 10 and 5% iron respectively.

Properties

| Individual SWNT Diameteri | ~0.8 – 1.2 nm |

| Individual SWNT Lengthii | ~100 – 1000 nm |

| Calculated Molecular Weightiii | ~3.4×105 – 5.2×106 Amu |

| Color | Black |

| Morphology | Dry powder of nanotubes bundled in ropes |

| Maximum Densityiv | 1.6 g/cm3 |

| Bulk Densityv | ~0.1 g/cm3 |

| TGA Residue as Fevi | |

| – Raw | |

| – Pure | |

| – Super Pure | |

| TGA 1st Derivative Peak Temperature | Raw ~350 – 410°C Pure ~470 – 490°C Super Pure ~510 – 540°C |

| TGA Onset Temperature | Raw ~350°C Pure ~440°C Super Pure ~450°C |

| Maximum Surface Areavii | 1315 m2/g |

| BET Surface Area | ~400 – 1000 m2/g |

| Buckypaper Resistanceviii | ~0.2 – 2Ω |

| Moisture Content |

SEM

TEM

![[cml_media_alt id='1023']TEM (2)[/cml_media_alt]](/wp-content/uploads/2014/10/hipco_3.jpg)

Raman

TGA Profile

Particle Size Analysis

i Diameter distribution measured by Unidym from TEM micrographs. Mean diameter ~1.0 nm.

ii Measured by Unidym using AFM.

iii Calculated. Lower limit assumes a SWNT with a diameter of 0.8nm and a length of 100nm. (0.8nm/0.245nm)(3.1414)(2 carbon atoms) = 20 carbons around the circumference. For every 0.283nm length there are 4×20=80 carbon atoms.

(100nm/0.283nm)(80)(12.01) = 339,505 Amu. Assuming 2 significant digits = 3.4×105. Upper limit assumes a SWNT with a diameter of 1.2nm and a length of 1,000nm. (1.2nm/0.245nm)(3.1414)(2 carbon atoms) = 31 carbons around the circumference. For every 0.283nm length there are 4×31 = 124 carbon atoms.

(1000nm/0.283nm)(124)(12.01) = 5,262,332 Amu. Assuming 2 significant digits = 5.2×106.

![[cml_media_alt id='1019']Calculated. Lower limit assumes a SWNT with a diameter of 0.8nm and a length of 100nm.[/cml_media_alt]](/wp-content/uploads/2014/10/hipco_4.png)

iv Calculated assuming single-wall nanotubes of diameter 1.0 nm arranged in crystalline “ropes” or “bundles” (inter-wall spacing 0.3 nm).

v Value provided is for standard purified SWNTs. Raw and some super pure grades lots will have lower bulk densities. Other product forms may have higher bulk densities.

vi 800°C in air. The reported figures assume that the residue is present in the product as elemental Fe, and that it is fully converted to Fe2O3 during the TGA analysis. Hence, the TGA residual as measured is multiplied by MW Fe2/MW Fe2O3 (1/1.43) to express the result as Fe.

vii Calculated using geometric arguments assuming an isolated tube. SSA for tubes in “ropes” will be less than the stated value. A. Peigney et al., Carbon 39 (2001), 507-514.

viii In-house, Unidym buckypaper conductivity test (4 point probe).

ix The following particle size histogram is indicative of the typical tertiary particle size distribution found in bulk powder. It does not represent secondary particles (aggregates of individual tubes also known as ropes or bundles) nor does it represent primary particle sizes (individual carbon nanotubes).

For further details, reach out to our

Sales Manager at sales@raymor.com or call +1 450.434.6266.

Large volume discounts available for large quantities.

Please contact us for more information.

![[cml_media_alt id='1021']Single-Wall Carbon Nanotubes[/cml_media_alt]](/wp-content/uploads/2014/10/hipco_1.jpg)

![[cml_media_alt id='1022']TEM (1)[/cml_media_alt]](/wp-content/uploads/2014/10/hipco_2.jpg)

![[cml_media_alt id='1014']Raman[/cml_media_alt]](/wp-content/uploads/2014/10/Raman.png)

![[cml_media_alt id='1016']TGA Profile[/cml_media_alt]](/wp-content/uploads/2014/10/TGA-Profile.png)

![[cml_media_alt id='1015']Particle Size Analysis[/cml_media_alt]](/wp-content/uploads/2014/10/Particle-Size-Analysis.png)